The Ultimate Guide To Motorcycle Parts New Zealand Specialists

Table of ContentsThe Only Guide to Motorcycle Parts New Zealand SpecialistsThe Of Motorcycle Parts New Zealand SpecialistsGetting The Motorcycle Parts New Zealand Specialists To WorkThe Motorcycle Parts New Zealand Specialists StatementsMotorcycle Parts New Zealand Specialists for BeginnersThe Single Strategy To Use For Motorcycle Parts New Zealand SpecialistsThings about Motorcycle Parts New Zealand SpecialistsMotorcycle Parts New Zealand Specialists Fundamentals Explained

So, connect to among our experts today.CNC machining innovation is promptly coming to be the focal factor of several various manufacturing procedures around the world as a direct outcome of its many benefits over various other approaches. Furthermore, the industries that manufacture motorcycles have actually obtained on board with this trend. One of the most cutting-edge firms are now creating their engine components and wheels making use of machining methods initially developed for motorbike components.

On the other hand, the effects of industry are the main emphasis of this short article. Let's obtain right into it. You might be wondering why we make use of. It is not difficult to fathom the factors that caused this outcome. Now that we have your focus let us clarify the rationale behind this contemporary advancement in the motorcycle manufacturing industry.

Motorcycle Parts New Zealand Specialists Can Be Fun For Anyone

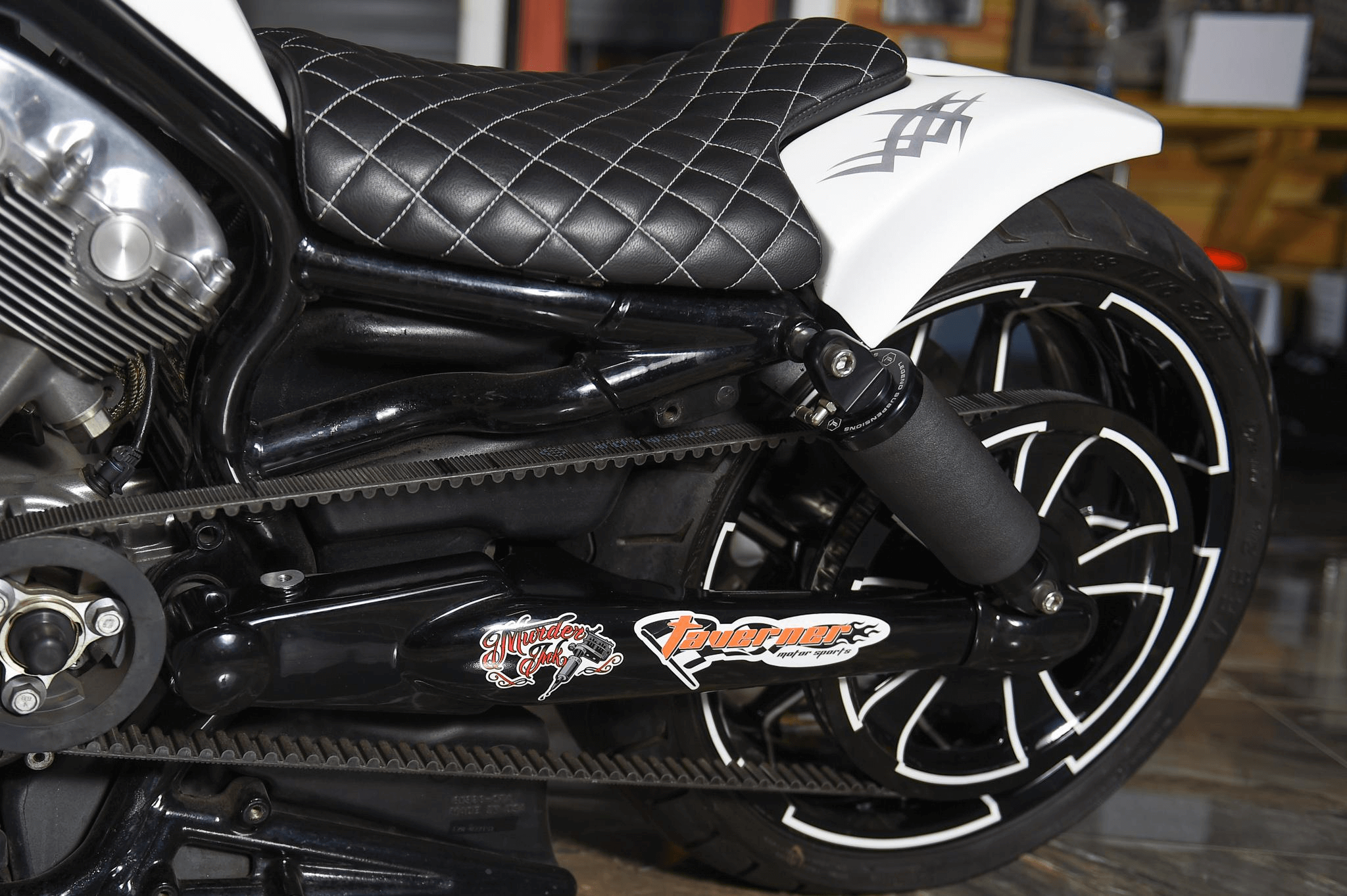

Furthermore, you have total control over the appearance of the components, also to the minute details. Occasionally, motorcyclists might make a decision to improve their ride by mounting aftermarket elements or changing the bike's remodeling. Once more, computer system mathematical control (CNC) machining is the most functional technique. Upgrades might be of any kind of kind and design you desire.

Unknown Facts About Motorcycle Parts New Zealand Specialists

CNC machining may be used to make practically all of a motorbike's steel and plastic parts. To continue, we'll go over numerous machined components for motorcycles.

Milling treatments are utilized to obtain the preferred level of wheel customization. An additional aspect of the motorbike that may be individualized is the tires.

Motorcycle Parts New Zealand Specialists Fundamentals Explained

When it comes to a car (or a motorcycle), one of the most crucial part is the engine. Numerous individuals mention it as the "heart" of the vehicle. On the other hand, the camshaft, the cyndrical tube head, and the pistons tend to be detailed and require layouts with a high level of accuracy.

Illumination is one more facility facet of customization. Use only high-grade products, however, given that these lights are important for the safety of motorcyclists and various other drivers or people when traveling, specifically at evening. Motorcycle fronts lights have 3 almosts all: the bulb, or light source, the lens, and the housing. Particularly, we tailor the lens and the real estate.

Milling procedures with a perfect surface would result in the lenses having a reflective top quality that is comparable to that of a mirror. The cover, on the various other hand, is not composed of fragile products; instead, it is constructed out of difficult polymers that can be machined into even more intricate patterns.

All About Motorcycle Parts New Zealand Specialists

They frequently have sophisticated geometries with a wealth of min details. Motorcycle producers typically cast these parts, however only for the manufacturing of bespoke parts. CNC machining is the method of option when producing unique pieces. Machining on five axes in today's globe is the methods whereby any design shape might be understood.

The success of the process is contingent on the mill cutters' capacity to determine subtle and complicated angles precisely. Pick Runsom for your customized motorcycle parts! We have the capacity to fabricate challenging and trendy parts making your bike matchless. The majority of are crafted from aluminum or steel alloys, each of which has its uses and advantages.

Below are a few examples of steels usually used in motorcycle element read this machining. Light weight aluminum is the key material utilized by firms concentrating on generating custom-made motorcycle components to produce the majority of these components. In the past, we would develop our engines out of cast iron. On the various other hand, light weight aluminum is swiftly coming to be the product of option, partially due to the truth that it is much more light-weight.

Zinc refers to another steel that is extremely light in weight and has great machining qualities because of its high mechanical toughness. This material might be formed into practically any more tips here type of form and maintains its measurements well. Also mission-critical elements that require a high level of precision might gain from their usage.

An Unbiased View of Motorcycle Parts New Zealand Specialists

Another steel that sees hefty usage in the manufacturing of CNC-customized elements is magnesium. It is amongst the lightest steels that are now easily accessible and has superb machinability features and stamina appropriate with its low weight. Among the drawbacks of magnesium is that its dust might conveniently capture fire.

Their most typical use in generating different bike components is fasteners, such as screws and bolts. Their reduced sensitivity to oxidation and rust makes them ideal for this usage.

4 Easy Facts About Motorcycle Parts New Zealand Specialists Explained

It appears that CNC transforming and milling are the fundamental processes. Alternative methods exist, such as drilling. Allow's investigate most of these machining techniques detailed. The CNC transforming method is considered a subtractive manufacturing approach. On top of my latest blog post that, it calls for keeping bars of material, usually plastic or steel, in setting and afterwards twisting a cutting tool to remove sections of the material as the product is turned.

These techniques are similarly important and generate parts with high accuracy and consistent quality. They are specifically: grinding, laser cutting, and exploration. The term "surface area finish" refers to post-processes after the preliminary machining phase. Motorcycle Parts New Zealand Specialists. The processes help boost the total high quality of the machined motorcycle elements. Below are the quick introduction, pros and disadvantages of five surface treatment methods.

The Definitive Guide to Motorcycle Parts New Zealand Specialists